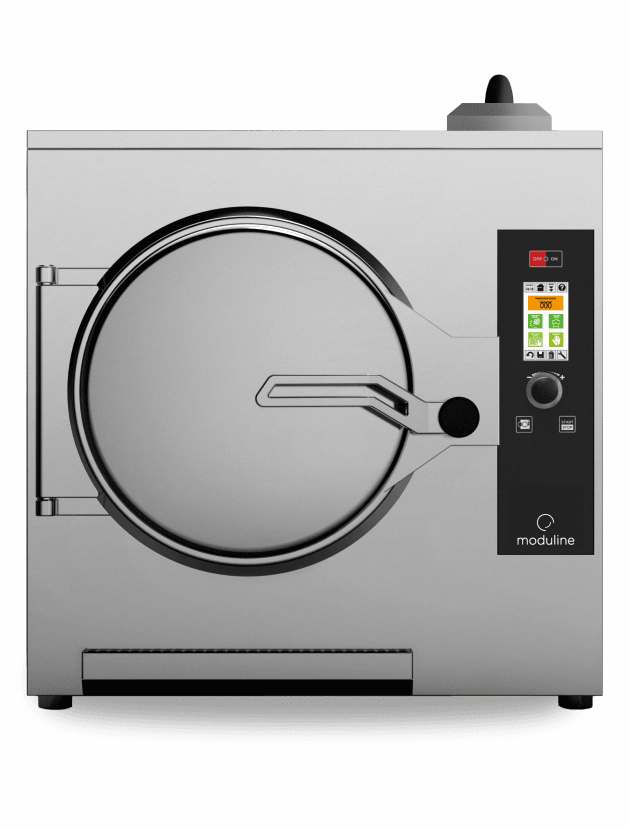

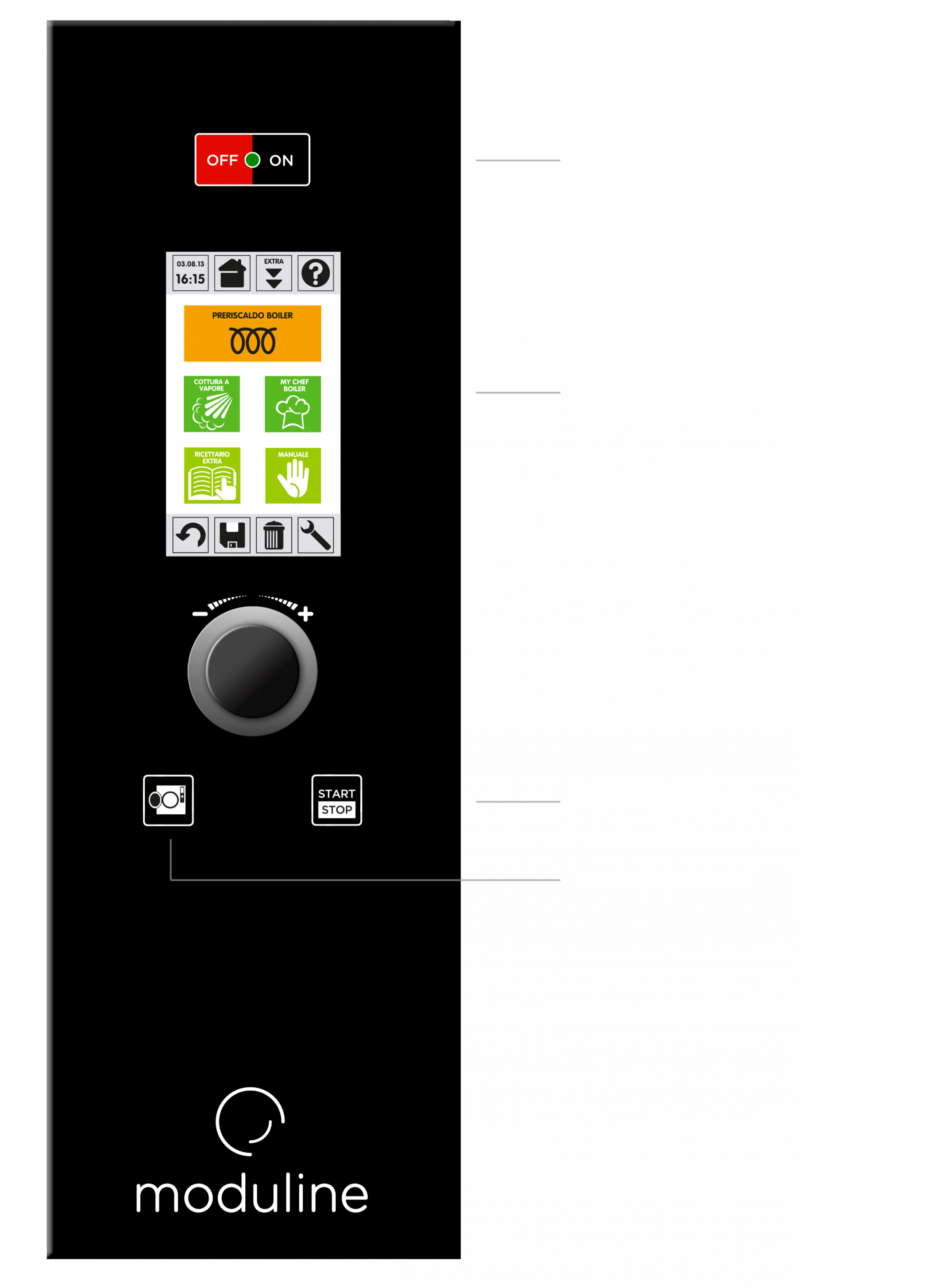

Pressure steamers: speed combined with quality

All the force of steam combined with the power of pressure.

All the force of steam combined with the power of pressure.

One is a 5 GN 1/1 with a 40mm gap, and the other is a 7 GN 1/1 with a 20mm gap.

Includes a valve to be mounted on the lids for inserting the core probe into the sample jar. The temperature is measured in the product, inside the sample jar, as a reference for the entire load.

One liter of product is required for a complete descaling cycle.

Allows the pressure in the condensate drain to be eliminated by bringing it upwards and leaving only the liquid elimination in the drain. This kit is necessary if the network drains cannot receive pressures higher than 0.5 Bar.

This can be purchased separately to protect the oven from unwanted limescale buildup in the boiler and components subject to steam injection into the chamber. During the initial installation, the oven software can be programmed with the mains water hardness parameter. Thanks to this 'set point', the oven automatically calculates the life of the filter until its cartridge needs to be replaced.

Participate in one of our inspirational events to discover how the Moduline equipment improves the productivity of your kitchen.

Klop | Pro Smart Kitchen Solutions is the exclusive distributor for Moduline in The Netherlands, Belgium and Luxembourg. We sell through a large dealer network. Please contact us so that we can connect you to the nearest dealer.